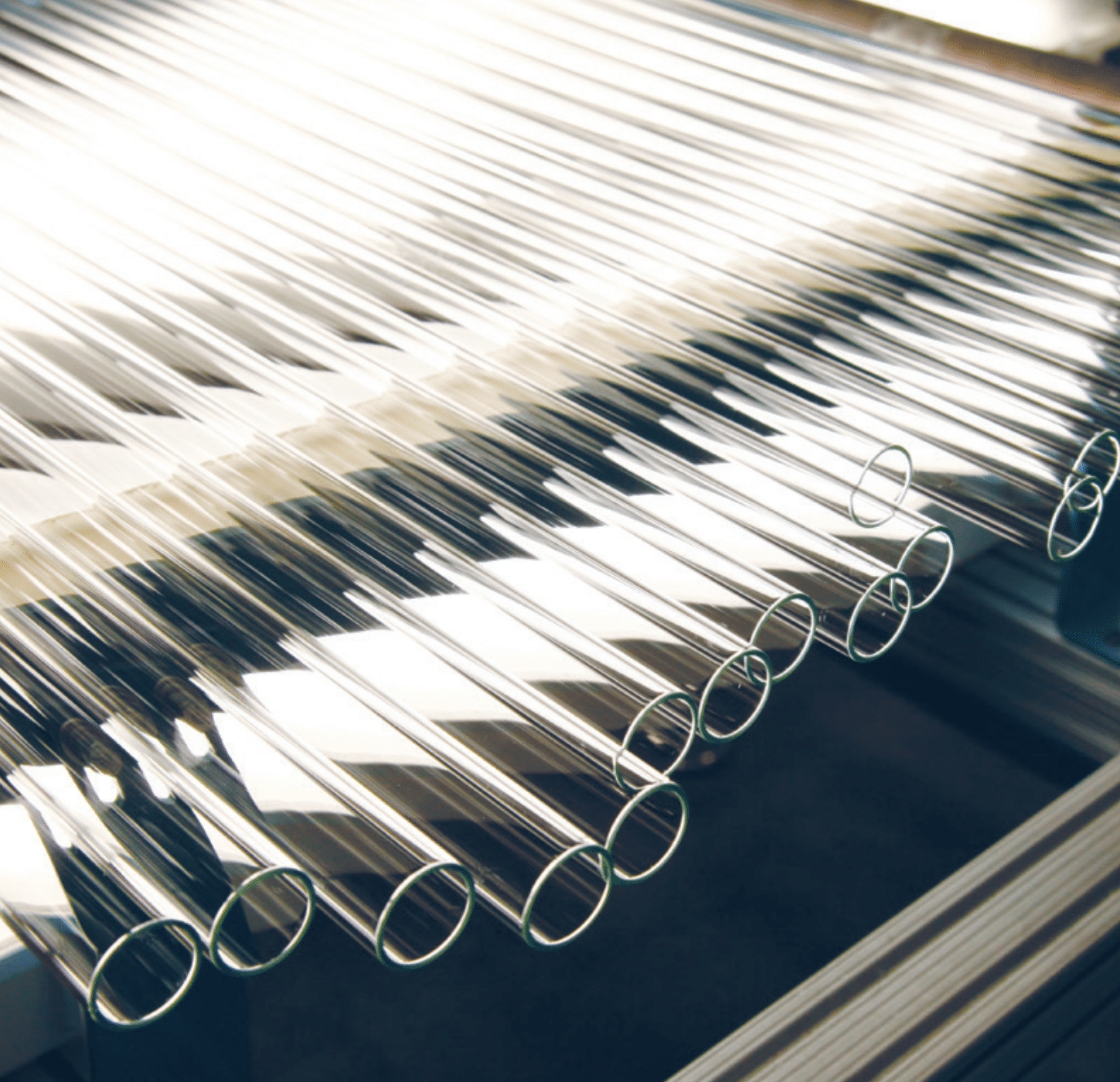

Medical glass, ampoules, vials & pre-fillable syringes

Glass tubing and advanced pharma packaging solutions for the diverse demands of the pharmaceutical and medical markets.

As a long-standing supplier of several billion high quality ampoules, our Japanese partner Nipro has the experience and expertise to offer unparalleled service in ampoule development and conversion-glass ampoules precisely shaped for pharmaceutical and medical applications

Extensive experience – advising you on glass tubing that best suits your needs

Nipro PharmaPackaging is a leading manufacturer of high quality glass vials for the global pharmaceutical industry. Their extensive experience enables them to develop and manufacture glass vials precisely meeting

the quality requirements of your drug product.

Premium Glass Quality

Nipro’s eNhance glass tubing NSV51 is an excellent raw material for ampoules. Their borosilicate glass (Type I) complies to prevailing Pharmacopoeias (USP, JP, EP) and offers excellent results for extractables and leachables. It contributes to drug stability during the entire shelf life.

Stringent quality systems (ISO 15378, ISO 14001, ISO 45001, ISO 50001, ISO 14644) govern all of their processes, resulting in ampoules strictly compliant to pharmacopeia (USP, EP, JP) and prevailing industry

standards.

Additionally, we offer a range of other Nipro products including several 2-part syringes and 3-part syringes with catheter tips, as well as laser-based cut pre-fillable syringes.

Read more

Read less