Liners for closures on plastic & glass nutraceutical bottles

Putting it all on the liner

Closure liners and seals perform critical packaging functions that are essential to product protection and consumer satisfaction – from tamper evidence, to safety, to freshness – liners cover it all.

Lining up the benefits

Closure liners and seals are integral to the success of product packaging, providing essential functions like gasketing for child-resistant closures and oxygen barriers for improved product freshness.

- Superior Product Protection: Strong seals and gasketing features minimize the risks of leaks, spills, and contamination

- Extend Shelf Life: Oxygen barriers seal in freshness and protect against spoilage, reducing product waste

- Enhance Safety: Tamper-evident seals and liners used in child-resistant closures ensure products are safely contained

- Differentiate Your Brand: Customization options enable brands to stand out under the cap, with space to add branding and usage instructions

Next generation, innovative closure liner solutions

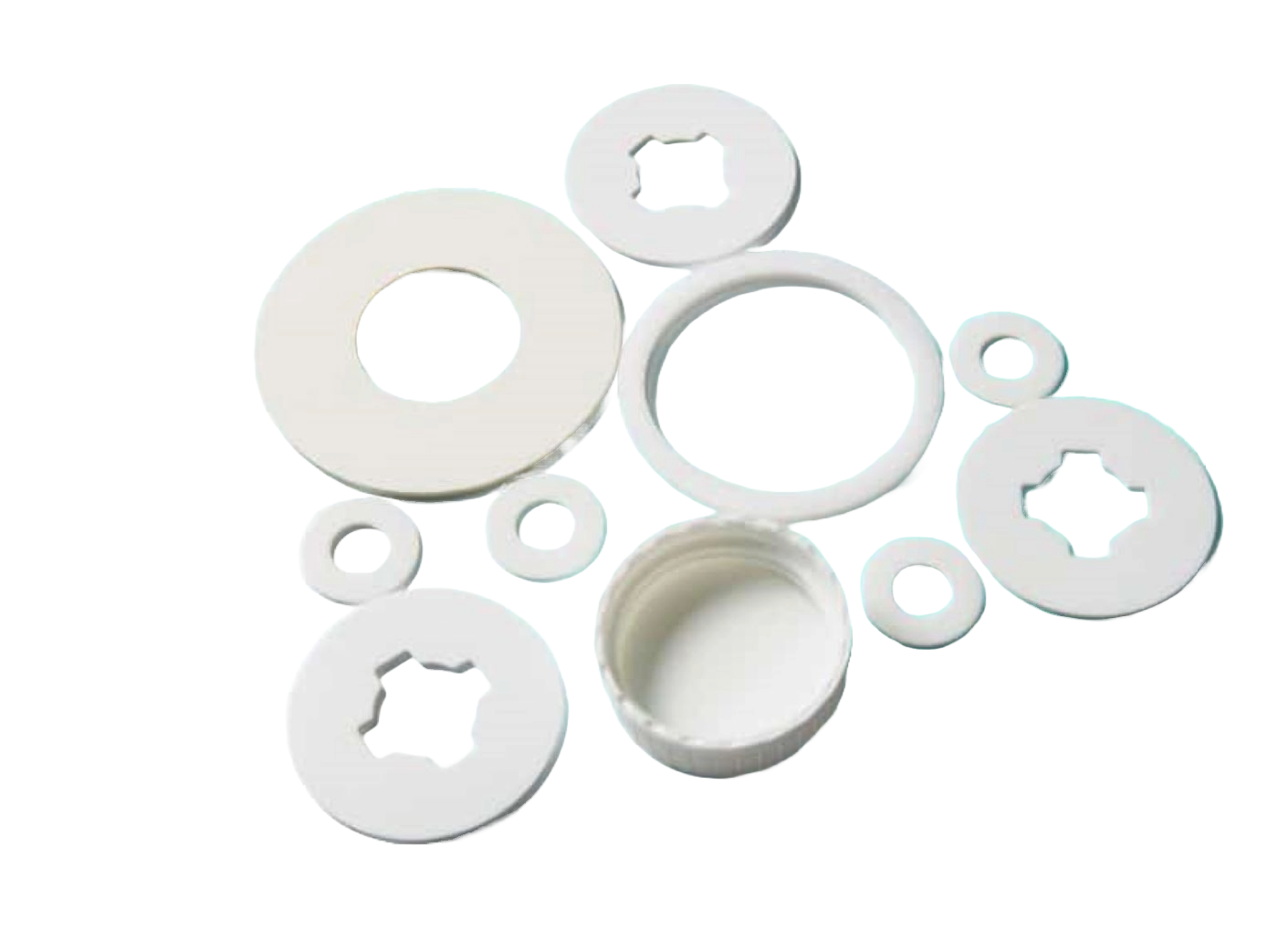

With our extensive lamination and extrusion processes, we can help you solve your toughest packaging challenges. Choose from a a broad range of closure liners, lidding and healthcare packaging in a variety of materials ranging from a one-piece induction seal to nine-layer extrusions and laminations.

Our liners feature:

- Trouble-free performance. Tekni-Plex closure liners are highly compressible which reduces closure back off and makes up for bottle finish variations.

- Customized liner construction, with several resin options available. Liners can be tailored in thickness, density and resilience.

We are also able to offer the following high specification materials from Tekni-Plex:

- Our standard re-seal liner material from Tekni-Plex is Tri-Seal F217, which is a co-extruded three-layer construction to provide solid polyethylene surfaces around an expanded polyethylene core. This gives the material far superior performance to single layer expanded polyethylene liners.

- Multi-layer foil backed liners, Tri-Foil® WP F-217® HY, which are a clear PET film bonded to a white LDPE film bonded to aluminum foil bonded to three-ply co-extruded F-217® HY liner. (Data Sheet downloadable here)

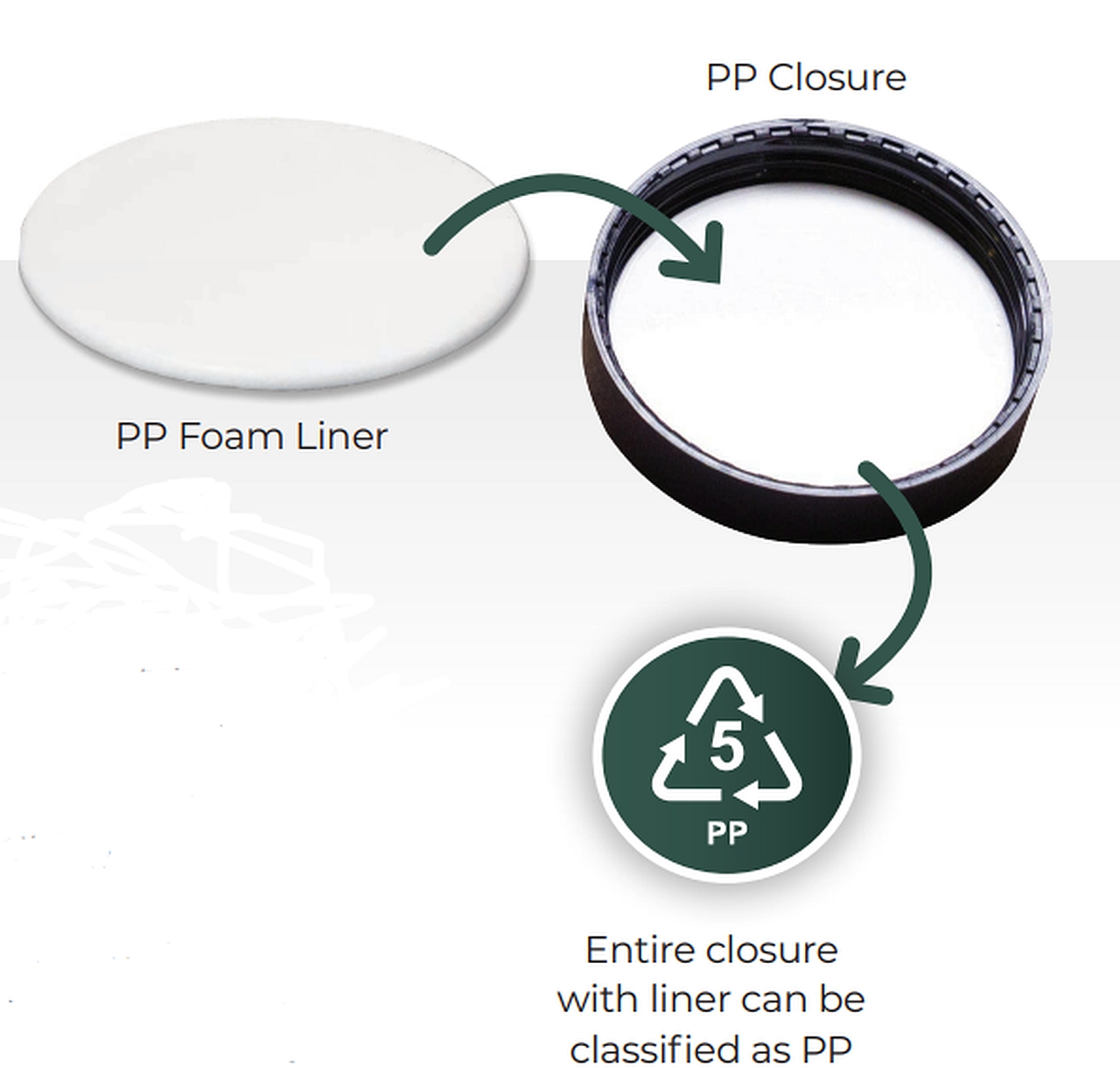

- Enhancing full recyclability, Tekni-Plex is committed to designing for mono-material packaging solutions with customers to encourage higher recyclability rates, such as Tri-Seal PP / F 948 100% polypropylene (PP) coextruded foam structure. An ideal solution for PP closures on jars, bottles, and containers.

- Extremely high barrier materials: white plastic exterior appearance with an internal foil layer to give near zero MVTR (Tri-Foil)

- Co-extruded high barrier materials for juices and beers that require ultimate barrier protection towards CO2 loss and O2 ingress without utilizing foil (Tri-Shield EVA).

- One or two piece induction heat seal materials for peelable or welded seals to PE, PP, PET, PVC or glass. Single or multi-use applications, wet or dry products. (Tri-Gard). HS035 IHS materials, suitable for use with metal caps and closures, available as cut discs or tape.

- Addtionally, the Tekni-Plex foam product line also offers enhanced barrier film construction to address specific product requirements

These products include multi-layer foil, film, barrier and paper structures for child-resistant, non-child-resistant, peelable or retortable pouches, and lidding.

Their closure liners can be found on millions of items throughout the world, including food, beverage, pharmaceutical, cosmetic, household/ industrial and agri-chemical products. Tri-Seal’s global manufacturing footprint in North America, Europe and Southeast Asia enables them to support brand owner needs around the world by providing the right solution.

Meeting the needs for your emerging pharmaceutical requirements

Continuous investment in research and development and a determined focus on innovations has led to smarter, sustainable, and safer material structures, dispensing and tubing products and technologies.

Our broad range of products include:

- sterilizable packaging substrates (thermoformable medical tray films, coated and uncoated Tyvek®, heat- and cold-seal coated paper and films, medical grade laminates, die-cut lids, labels and cleanroom bags)

- pharma blister films and foil, film and paper laminates, unit- and multi-dose containers

TekniPlex provides quality flexible packaging to hold and protect market-leading healthcare and personal care products world-wide.

Barrier Protection and Seal Integrity

These products include multi-layer foil, film, barrier and paper structures for child-resistant, non-child-resistant, peelable or retortable pouches and lidding. We have the capability and flexibility to deliver upon your requirements: large, small, or in between.

TekniPlex has a proud history of over eight decades of demonstrated quality, service, and performance coupled with a commitment to product development and investment to meet today and tomorrow’s packaging needs.

TekniPlex invented F 217, for coextruded closure liner material used in a variety of pharmaceutical and cosmetic applications. TekniPlex is also a leader in pressure-sensitive closure liners, as well as a leading producer of tamper-evident and peelable induction-seal closure liners.

Read more

Read less